Xa kuziwa ekwenzeni iinxalenye zeplastiki, ukukhetha inkqubo efanelekileyo kubalulekile ukuqinisekisa umgangatho, ukuphumelela kweendleko, kunye nokusebenza kakuhle.Iindlela ezimbini ezidumileyo zokuvelisa iinxalenye zeplastiki kukuphosa urethane kunye nokubumba inaliti.Zombini zinezibonelelo zazo ezizodwa kunye nokusetyenziswa, kodwa ukukhetha eyona ilungileyo kwiprojekthi yakho kuxhomekeke kwizinto ezahlukeneyo.Kule bhlog, siza kuphonononga umahluko, izibonelelo, kunye neemeko ezifanelekileyo zokusebenzisa urethane cast kunye nokubumba inaliti ukukunceda wenze isigqibo esinolwazi.

Ukuqonda iUrethane Casting

Ukwenziwa kweUrethaneyinkqubo yokuvelisa apho i-polyurethane yolwelo igalelwa kwi-silicone mold ukwenza iinxalenye.Le ndlela ilungele ukuvelisa iincinci ezincinci kunye neeprototypes ezinokuthembeka okuphezulu kunye neenkcukacha eziyinkimbinkimbi.

Izinto eziluncedo kwiUrethane Casting:

Ixabiso Elisebenzayo kwiMithamo ePhantsi:Ukwenziwa kweUrethane kunoqoqosho ekuveliseni iibhetshi ezincinci, kuyenza ibe lolona khetho lubalaseleyo kwiiprototypes kunye nokuqhutywa okufutshane kwemveliso.

Ixesha lokuguqula ngokukhawuleza:Ngokuphoswa kwe-urethane, ulungiselelo lokungunda kunye nenkqubo yokuvelisa ikhawuleza, ivumela iprototyping ekhawulezayo kunye nokuphindaphinda.

Iinkcukacha eziphezulu kunye noMgangatho wokuGqiba:Ukwenziwa kweUrethane kunokuvelisa iinxalenye ezineenkcukacha ezintsonkothileyo kunye nokugqitywa komphezulu ogudileyo, ukulinganisa ngokusondeleyo iindawo zokugqibela zemveliso.

Izinto eziNyeezohlukeneyo:Uluhlu olubanzi lwemathiriyeli ye-urethane iyafumaneka, ibonelela ngeempawu ezahlukeneyo njengokuguquguquka, ukuqina, kunye nokuqina.

Iindleko zezixhobo ezisezantsi:Iimolds ze-silicone ezisetyenziselwa ukubunjwa kwe-urethane zingabizi kakhulu ukuvelisa xa kuthelekiswa nokubunjwa kwentsimbi okufunekayo ekubunjweni kwenaliti.

Usetyenziso olululo lweUrethane Casting:

• Iimodeli zePrototyping kunye neengqikelelo

• Amacandelo angokwezifiso kwimveliso yomthamo ophantsi

•Uvavanyo lwangaphambi kokuveliswa

• Uvavanyo olusebenzayo lwamalungu anejiyometri enzima

Ukuqonda Ukubunjwa kwesitofu

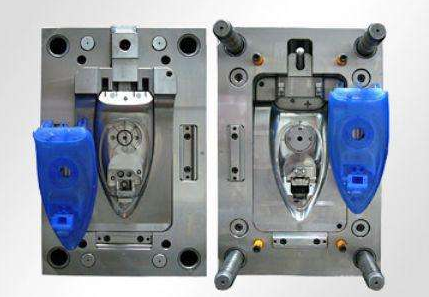

Ukubumba i-injection yinkqubo yokuvelisa apho iplastiki etyhidiweyo ifakwe kwi-mold yesinyithi phantsi koxinzelelo oluphezulu ukuvelisa iindawo.Le ndlela isebenza kakhulu kwimveliso yobuninzi kwaye inokuvelisa iinxalenye ezinomgangatho ohambelanayo kunye nokuchaneka okuphezulu.

Izinto eziluncedo zokuMbumba ngesitofu:

Iindleko eziSebenzayo kwiMiqulu ephezulu:Ngelixa iindleko zokuqala zezixhobo ziphezulu, ukubumba inaliti kuba ukonga ngakumbi kwintsebenzo enkulu yemveliso ngenxa yeendleko eziphantsi ngenxalenye nganye.

Ukuchaneka okuPhezulu kunye nokuhambelana:Ukubumba isitofu kunika ukuphinda okugqwesileyo, kuqinisekisa ukuba indawo nganye eveliswayo iyafana kwaye iyahlangabezana nemigangatho engqongqo yobulunga.

Uluhlu olubanzi lweMathiriyeli:Uluhlu oluninzi lwe-thermoplastics lunokusetyenziswa ekubunjweni kwesitofu, ukubonelela ngeenketho zamalungu afuna iimpawu ezithile zoomatshini kunye nokusebenza.

Imveliso esebenzayo:Ukubunjwa kwe-injection kunokuvelisa amawaka eenxalenye ngexesha elifutshane, okwenza kube yinto efanelekileyo yokuvelisa umthamo ophezulu.

Ukuqina kunye Nobude Obude:Iimbumba zetsimbi ezisetyenziselwa ukubunjwa kwe-injection zihlala zihlala kwaye zinokuvelisa inani eliphezulu leengxenye ngaphambi kokufuna ukugcinwa okanye ukutshintshwa.

Usetyenziso oluLungelo lokuBunjwa kwesitofu:

•Imveliso ephezulu yomthamo wamalungu eplastiki

•Imveliso yabathengi kunye ne-electronics

•Amacandelo ezemoto

•Izixhobo zonyango kunye nokupakishwa

•Amacandelo oshishino kunye nezorhwebo

Ukuthelekisa iUrethane Casting kunye ne-Injection Molding

Ixabiso:

•Ukwenziwa kweUrethane:Iindleko zokuqala eziphantsi kunye neendleko zezixhobo;iindleko-esebenzayo kwimveliso umthamo ophantsi.

•Ukubunjwa kwesitofu:Iindleko eziphezulu zokuqala zokusebenzisa izixhobo kodwa ziphantsi ngenxalenye nganye yeendleko zemveliso enkulu.

Umthamo weMveliso:

•Ukwenziwa kweUrethane:Eyona ifaneleke kakhulu kwimiqulu ephantsi ukuya ephakathi (i-1-1000 iinxalenye).

•Ukubunjwa kwesitofu:Efanelekileyo kwimveliso ephezulu (i-1000+ iinxalenye).

Ixesha lokukhokhela:

•Ukwenziwa kweUrethane:Ixesha elikhawulezayo lokukhokela kwiibhetshi ezincinci kunye neeprototypes.

•Ukubunjwa kwesitofu:Ixesha elide lokukhokela ngenxa yokwenziwa komngundo kodwa imveliso ekhawulezayo yemithamo ephezulu.

Ukuntsonkotha kwenxalenye kunye neenkcukacha:

•Ukwenziwa kweUrethane:Igqwesileyo kwiijometri ezinzima kunye neenkcukacha ezintle.

•Ukubunjwa kwesitofu:Iyakwazi ukuchaneka okuphezulu kodwa inokufuna uyilo lokungunda oluntsokothileyo noluxabisayo kumacandelo antsonkothileyo.

Ukukhetha Inkqubo eyiyo yeProjekthi yakho

Isigqibo phakathi kokubunjwa kwe-urethane kunye nesitofu sixhomekeke kwizinto ezininzi:

•Umthamo weMveliso:Kwimithamo ephantsi ukuya kwephakathi, ukufakwa kwe-urethane kuneendleko eziphezulu.Kwimveliso ephezulu, ukubumba inaliti lolona khetho lungcono.

•Uhlahlo lwabiwo-mali:Qwalasela iindleko zokuqala zezixhobo kunye neendleko zenxalenye nganye.Ukwenziwa kweUrethane kufuna utyalo-mali lwangaphambili olusezantsi.

•Ixesha lokukhokhela:Ukuba ufuna ujiko olukhawulezayo lweeprototypes okanye ukubaleka okufutshane, ukuphosa urethane kunika amaxesha okukhokela akhawulezayo.

•Ukuntsonkotha kwenxalenye:I-urethane casting iyagqwesa ekuveliseni iinxalenye ezineenkcukacha ezintsonkothileyo, ngelixa ukubumba inaliti kubonelela ngokuchaneka okuphezulu kobuninzi.

•Iinkcazelo Ngeempawu zeMathiriyeli:Vavanya iimfuno zemathiriyeli ezithile kumalungu akho kwaye ukhethe inkqubo enikezela ngezona zinto zibalaseleyo.

Ukuqukumbela

Zombini ukubunjwa kweurethane kunye nokubumba inaliti kuneengenelo zazo ezahlukileyo kwaye zilungele iimfuno zeprojekthi ezahlukeneyo.Ngokuqonda amandla kunye nemida yenkqubo nganye, unokwenza isigqibo esinolwazi esihambelana neemfuno zeprojekthi yakho, uhlahlo lwabiwo-mali, kunye nexesha.Nokuba ufuna iiprototypes ezineenkcukacha eziphezulu okanye imveliso enkulu, ukukhetha indlela efanelekileyo yokuvelisa kuya kuqinisekisa impumelelo yeprojekthi yakho.

Ixesha lokuposa: Jun-14-2024